Business

AP Systems, moving forward into the world with a passion for endless research and technological developments

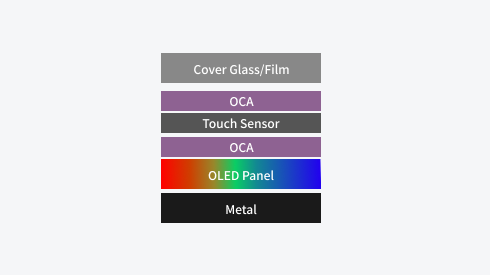

Display(Back-End Process)

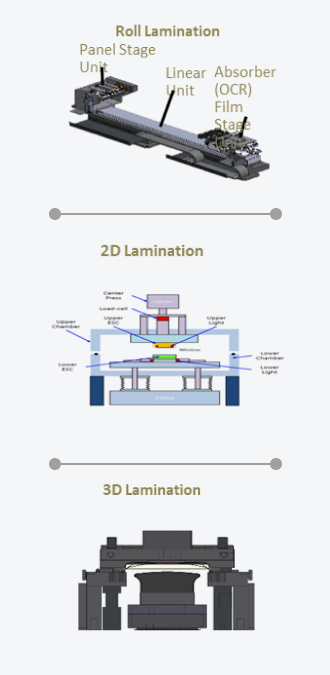

Module Lamination

Vacuum Chamber Lamination

- Automatically inputs/supplies panels and raw materials (UTG, PSA), and performs lamination.

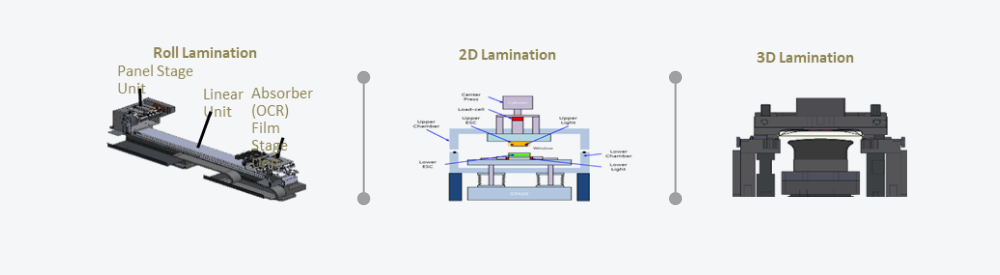

- Applicable to 2D/3D/Automotive/ROLL/4side curve PNL process

Technology

- Optimizing the design of silicon PAD applied to 3D construction method for new products

- Optimize design and improve product quality through particle path and airflow analysis

- Auto Mapping and OFFSET Auto application due to APC algorithm

- Minimize JOB CHANGE time by providing Auto Camera Calibration

- Provide 2D & 3D Lamination Change (by Lego Block detachable mode)

- Provides function to minimize defect rate by providing ESC foreign body inspection function

Specification

| Pressing Capacity | 2.5TON ~ (TBD) |

|---|---|

| Align style and point(bonding) | VISION / 2parts_4parts can be aligned |

| Bonding precision | < ±80um (TBD) |

| Material size | 3”~ (TBD) |

| Input style | Magazine AUTO TYPE (TBD) |

| Application | Phone, Foldable, Tablet, Note Book Process for Display) |