Business

AP Systems, moving forward into the world with a passion for endless research and technological developments

Semiconductor

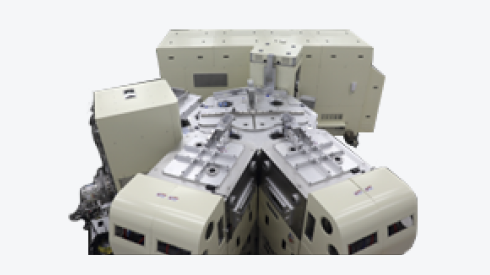

Sputter System

KORONA™ PVD600_ Advanced Package Process

- Semiconductor Advanced Package Sputter

- Following the high capacity, faster, and smaller trends of semiconductor devices, semiconductor Packaging technology has also been developed from the

previous Wire bonding to Flip Chip, and recently to FOWLP/FOPLP and 3D Packaging. - As the semiconductor Packaging technology is being developed, we at AP Systems, are providing client companies with Sputtering equipment for manufacturing

relevant metal films (CPB,UBM and RDL)

Technology

- Substrate Shift Detection & Align Technology when entering into each

chamber - ESC technology for low temperature (-20℃) to secure optimal process

(@ Preclearing & Process) - Multi Plate Heating System composition technology for Long Term Degas Time

(at least 30mins.) & High Temp. Uniformity

- Plasma Etching Chamber in the CCP form applied in Situ Pasting for the

Lower Particles - Magnetron Sputtering Source technology for High Film Quality and Film

Uniformity (Magnetron Scan & Tilt for FOPLP) - Verified Software Tool (Easy ClusterTM) operating technology applied to various semiconductor equipment

Features

PVD600: CPB & FOWLP

- Board Information: Diameter 300mm including EMC (Epoxy Molding Compound)

- EFEM, 2LoadLock, Octagonal Transfer Chamber, 2Multi_Degas Chamber,

2Pre-Cleaning Chamber (CCP) & 2Process Module

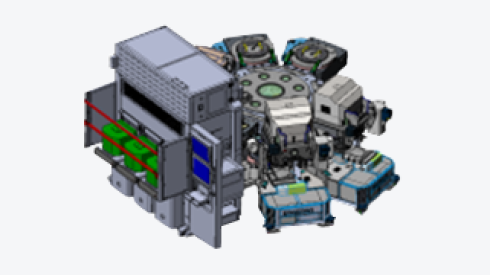

PVD600_R450: FOPLP

- Board Information: Rectangular (Approximately 400 x 500mm) type with PCB

- EFEM, 2LoadLock, Octagonal Transfer Chamber, 2Multi_Degas Chamber,

2Precleaning Chamber (CCP) & 2Process Module(Vertical Process)

Specification

| Temperature Uniformity> (@ Degas of 300℃) |

≤ 5% |

|---|---|

| Etch Uniformity (@ Precleaning) |

≤ 7% |

| Film Uniformity (@ Process) |

≤ 5% |

| Throughput (@ Ti : 1000Å, Cu : 3000Å) |

≥ 33 sheets/hr(@ Si기판), ≥ 24 sheets/hr(@ EMC & PCB 기판) |

Technology

- Wafer Shift Detection & Align Technology when entering into each chamber

- ESC technology for low temperature (-20℃) to secure optimal process

(@ Precleaning & Process) - Dual Heating System composition technology for Fast Temperature Rising

& High Temperature Uniformity

- Plasma Etching Chamber in the ICP form for Lower Damage & High Throughput

- Magnetron Sputtering Source technology for High Film Quality and Film

Uniformity (Magnetron Scan & Tilt for FOPLP) - Verified Software Tool (Easy ClusterTM) operating technology applied to various semiconductor equipment

Features

PVD600: Single Backbone

- EFEM, 2LoadLock, Octagonal Transfer Chamber, Single Degas Chamber, Pre-

Cleaning Chamber (ICP) & 2Process Module

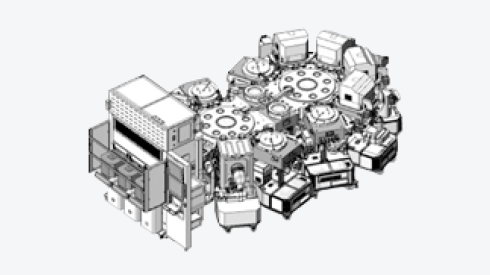

PVD1000: Dual Backbone

- EFEM, 2LoadLock, 2Octagonal Transfer Chamber, 2Single Degas Chamber,

2Precleaning Chamber (ICP) & 4Process Module

Specification

| Common | Temperature Uniformity(@ Degas of 300℃): ≤ 5% |

|---|---|

| Etch Uniformity(@ Pre-Cleaning) :≤ 5% | |

| Film Uniformity(@ Process) : ≤ 3% | |

| Throughput (@ Ti : 250Å, Al : 6000Å, TiN : 250Å) |

PVD600 : ≥ 39 sheets/hr |

| PVD1000 : ≥ 52 sheets/hr |