Business

AP Systems, moving forward into the world with a passion for endless research and technological developments

Semiconductor

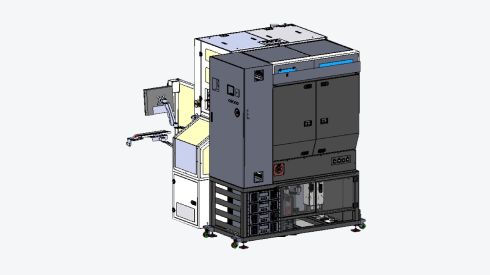

Descum System

KORONA™ DSC200

- Semiconductor Descum System

- It is a plasma treatment system that removes scums in the lateral walls of the pattern before electroplating, or performs surface modification to improve adhesive power, when forming Bump to be used in Flip Chip Bonding in the wafer.

Technology

- ICP Antenna design technology (high density/low damage plasma)

- Control process uniformity (design optimized pedestal and edge ring)

- Plasma stability (design optimized interior of the chamber)

- Functional Transfer Robot (wafer alignment)

Features

- High etch rate using the helical inductively coupled plasma

- Large Diameter Plasma Reactor and Optimized Chamber Inner Structure

- Easy to control process uniformity

- Minimized the CoC (Cost of Consumables)

Specification

- Helical Resonance ICP Plasma(27.12MHz)

(Ion Density: >1E12 cm-3 , Electron Temperature < 1eV) - Cooling Pedestal: 0 ~ 40°C

- Composed of minimized layout(foot print) of 2 independent chambers